Copper plating is an important component of the copper/nickel/chromium system used to protect and decorate coatings.

Flexible, low porosity copper plating plays an important role in improving adhesion and corrosion resistance. Copper cladding is also used for local sealing in case hardening, metallization of printing plate bores and as a surface layer for the printing roll. A layer of colored copper, coated with an organic film after chemical treatment, can also be used for decoration. The most common solutions for copper plating are cyanide, sulfate and pyrophosphate solutions.

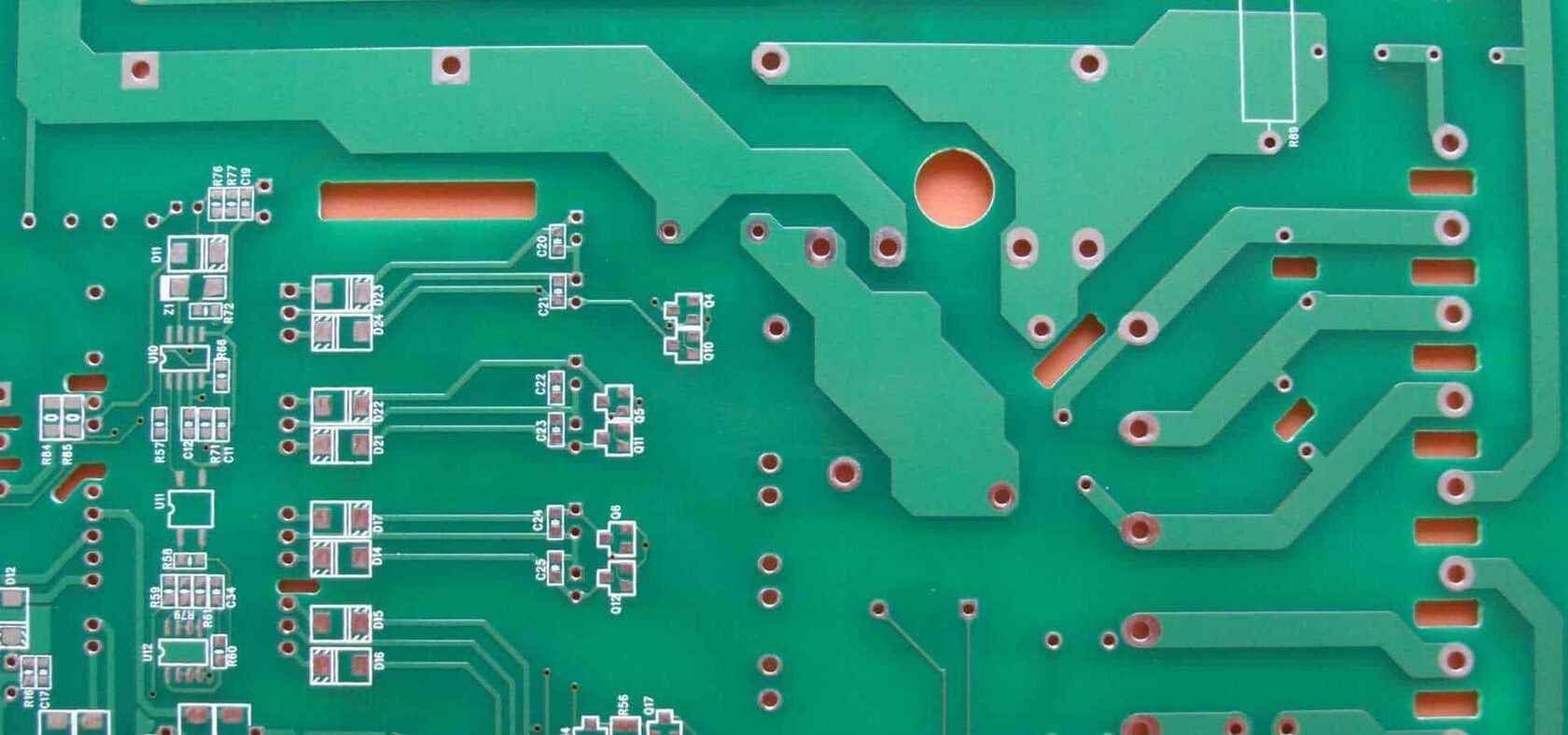

Copper plating is an autocatalytic redox reaction. First, an activator is used to adsorb a layer of active particles, usually metallic palladium particles, onto the surface of an insulating substrate. Copper ions are first reduced on these active palladium metal particles, and then the reduced copper metal crystal nuclei themselves become a catalytic layer of copper ions, allowing the copper reduction reaction to continue on the surface of the new copper crystal nuclei. Electroless copper plating is widely used in PCB manufacturing, with the most common method being the plating of PCB holes using electroless copper plating.

Copper plating is an autocatalytic redox reaction. First, an activator is used to adsorb a layer of active particles, usually metallic palladium particles, onto the surface of an insulating substrate. Copper ions are first reduced on these active palladium metal particles, and then the reduced copper metal crystal nuclei themselves become a catalytic layer of copper ions, allowing the copper reduction reaction to continue on the surface of the new copper crystal nuclei. Electroless copper plating is widely used in PCB manufacturing, with the most common method being the plating of PCB holes using electroless copper plating.